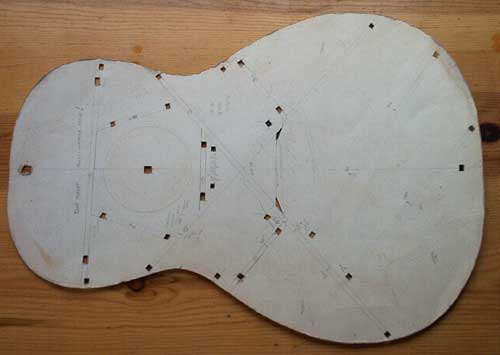

Hey Ross, what you can do is play connect the dots with the plan. You can lay it over the top and line up the edges of the plan with the edges of the wood itself (use your ruler here to get the plan in the right place), now you could take a tack and tack the centerlines of the braces (outside of the body edge) to the wood, now you have a dot to line up with the opposite end, lay down the straight edge and connect the dots

. This is just a guess as I have never done it this way, I just measure everything from the top of the neck block down and the center line out, but the connect the dots may work

. This is just a guess as I have never done it this way, I just measure everything from the top of the neck block down and the center line out, but the connect the dots may work

Do you have Guitar making: Tradition & Tech (Cumpiano/Nat...who ever) they lay it out pretty good there.